Addressing Drillhole Backlogs to Enhance Mineral Resource Accuracy

Sound Mining deployed experienced geologists to log, sample, and process 5,600m of core, reducing the backlog by 62%. This enabled an accurate resource estimation, improved operational efficiency, and allowed the client to proceed with critical mine planning.

Challenges:

Backlog Hindering Mineral Resource Updates

Managing Exploration Data Amid Resource Constraints:

Significant Backlog:

Significant Backlog:Exploration drilling continued without being logged or sampled due to the lack of an on-site exploration geologist, resulting in unutilised data from 2023 drillholes.

Operational Impact:

Operational Impact:The backlog prevented these drillholes from being included in the updated mineral resource estimates, which, in turn, affected reserve estimation and mine planning accuracy.

Time Sensitivity:

Time Sensitivity:An expedited solution was required to reduce the backlog without compromising data quality.

The primary objective was to clear the backlog by logging and sampling available drillholes, ensuring the data could be integrated into the client’s resource model.

Sound Mining's Solution

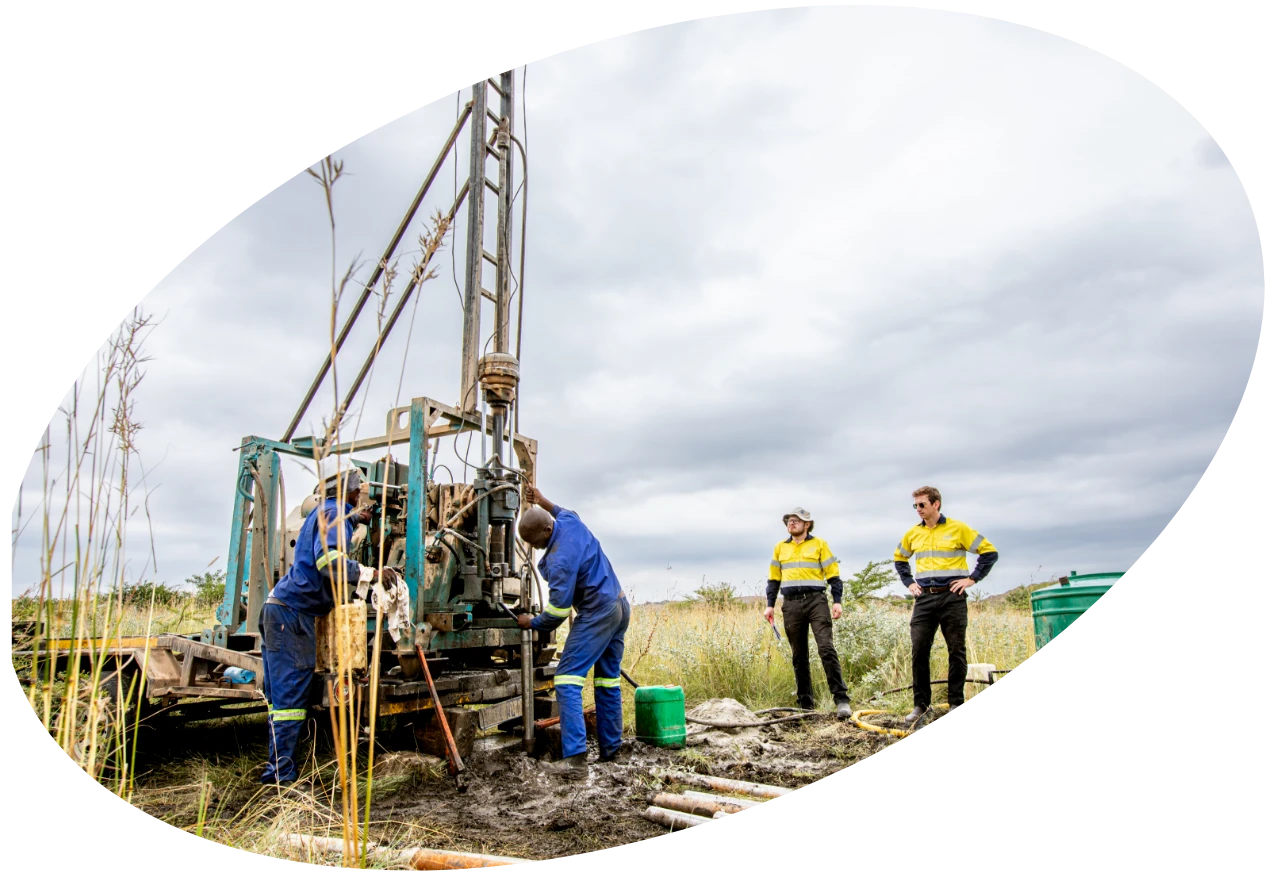

Comprehensive Logging, Sampling, and Quality ControlSound Mining stepped in to deliver a streamlined solution, resolving the backlog and positioning the client for improved resource and reserve planning.

Sound Mining deployed two experienced geologists equipped with the necessary tools to tackle the project.

The Process Involved

DETAILED LOGGING

Geological, RQD (Rock Quality Designation), and core recovery logging of 5,600m of core from 13 drillholes.

Outcome:

Efficient Backlog Management and Enhanced Resource PlanningWith Sound Mining’s sound solution, the following results were achieved:

- 62% reduction in the backlog of 2023 drillholes.

- Enhanced capacity for the next mineral resource update by incorporating previously unutilised drillhole data.

- Significant decrease in operational inefficiencies.

- Independent resolution of the backlog allowed the client’s in-house MRM (Mineral Resource Management) team to focus on day-to-day geological studies and production sampling.

- Greater orebody delineation for accurate resource and reserve planning.

Partner with Sound Mining for proven mineral expertise

With a track record of delivering tailored solutions, Sound Mining provides the technical expertise needed to overcome complex mineral challenges. From resource estimation to operational efficiency, our team ensures accurate data, streamlined processes, and optimised planning.

Contact us today to learn how we can support your operations.